Tunnel dryers with pellet burner

About the product

The dryers are designed to dry fruits, vegetables, forest fruits and medicinal herbs, previously prepared for dying.

The drying process technology upholds the natural color, original flavor and aroma and nutritional value.

The dryers are designed for drying following products:

- Fruits: plum, peach, apricot, apple, mango, sour cherry, cherry, blueberry, strawberry and similar fruit.

- Vegetables: onion, carrot, potato, celery, paprika, cauliflower, green bean, cabbage, mushroom and similar

- Medicinal herbs: mint, chamomile, elder tree, acacia flower, linden flower and similar

- Forest fruits: rosehip, mushroom, wild apple, wild garlic and similar

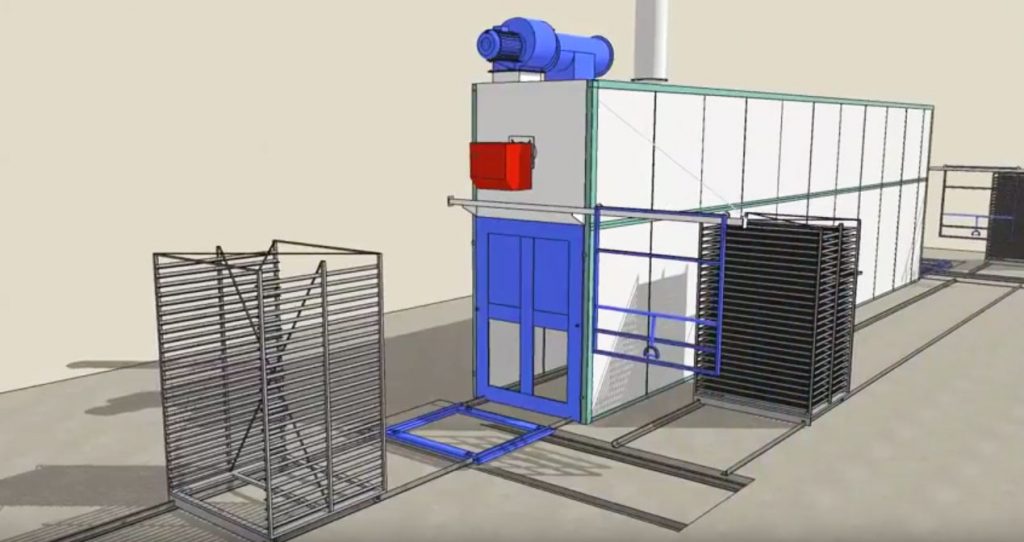

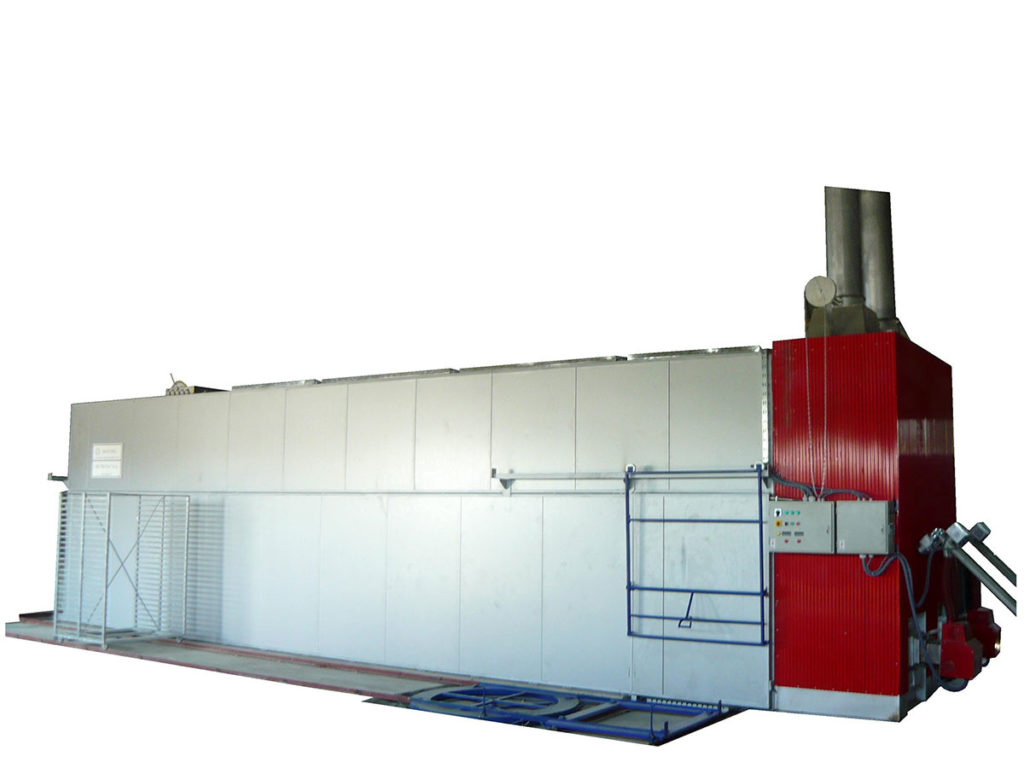

The tunnel dryer can be made of panels or bricks.

Panel construction consists of high thermal conductivity sandwich panel, while the brick construction is done by building tunnels from hollow bricks.

Tunnel dryer is a direct continuous type of dryer and a large-scale dryer.

The material to be dried is spread on trays, that are stacked on trolleys with plenty of space between the trays, allowing the air to passage. The trolleys have caster wheels and this allows greater flexibility inside the plant. The trolleys are guided in the tunnel by tracks and moved by hand through a tunnel in one direction.

The trolley with wet material placed on trays enters the tunnel from one side and leaves the tunnel on the other side. For every trolley with dried material taken out of the tunnel, a trolley with wet material is pushed inside the tunnel from the other side, which makes all the trolleys in the tunnel advance by one position.

The tunnel is supplied with heated air current that enters the tunnel at one side and is removed at the other end. The moving air also removes the evaporated moisture and it passes through the exhaust. The air that needs to be heated is blown over the system of hot tubes, that is connected with the furnace.

The tunnel is supplied with an automatic temperature and air speed regulation system unit.

The pellet burner is equipped with pellet container and modern system for automatic temperature control.

Technical information

| C-3000 | C-6000 | C-10000 | ||

| Capacity | kg / 24h | 3000 | 6000 | 10000 |

| Tunnel dimensions | A (mm) | 1200 | 1200 | 1300 |

| B (mm) | 1885 | 1885 | 1885 | |

| C (mm) | 7500 | 10500 | 14500 | |

| Dryer dimensions | D (mm) | 1340 | 1340 | 1440 |

| E (mm) | 3150 | 3150 | 3250 | |

| F (mm) | 8640 | 11640 | 15640 | |

| Drying tray dimensions | širina (mm) | 500 | 500 | 500 |

| dužina (mm | 1100 | 1100 | 1200 | |

| Maximum air flow | m3/h | 24000 | 24000 | 32000 |

| Fan power | kw | 11 | 11 | 15 |

| Burner power | kw | 150 | 280 | 420 |

| Maximum drying temperature | °c | 90 | 90 | 90 |

| Number of carts | kom Pcs | 7 | 10 | 12 |

| Numberof frames | kom Pcs | 350 | 500 | 600 |

| Pellet consumption | kg peleta/ h | 18 | 33 | 50 |

Video